Fluidifier additive to the crude oil mass modifies the thixotropic characteristics of the crude oil mass to achieve a more favorable kinematic viscosity without altering the initial composition of the crude oil mass. This is the process of fluidification by molecular dispersion which employs new chemistry involving the anionic/nonionic relationship of the crude oil mass and the fluidifier additive.

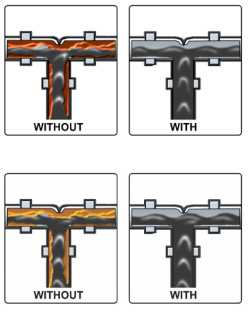

Fluidifier additive achieves reduction of turbulence induced drag in the pipeline of the crude oil mass due to a rearrangement of the bonds between atoms in the crude oil without altering the inherent properties of the crude oil. This decreases pressure in the pipeline resulting in a higher flow stream at the same pressure. This is new chemistry as the alteration in the bonds between the atoms within the crude oil creates an energy demand which is recovered by the energy previously lost in the region of the turbulent flow.

Fluidifier additive to the crude oil mass can serve as a Drag Reducing Agent by positively altering the frictional pressure occurring in a pipeline or other conduit. Fluidifier additive also can be enhanced to accomplish many more beneficial functions as well if the underlining chemistry is properly designed as a “building blocks” system.

Fluidifier additive to the crude oil mass compels a full understanding of complex interaction of the varying properties of different crude oil mass such as the type of crude oil (asphaltic or paraffinic, etc.), composition and pH of the water, temperature, extent of compression by pressure, dissolved gas, contact time, and concentration of polar molecules.

Fluidifier additive to the crude oil mass speeds the movement of the crude oil mass of varying API degrees and viscosity from the production and extraction casing through the upstream gathering system, midstream pipeline, tanker, storage tanks and delivery flow stream system and downstream at the refinery.

Fluidifier additive facilitates the uniform and continuous flow of the crude oil mass to prevent clogged production wells and flow stream processes and prevent interruption of the production and flow stream delivery or renewed production of inactive wells.

The OilFlux™ “W” series of new chemistry Fluidifier additives accomplishes all of the following desired beneficial features of fluidification, hence the name OilFlux™, as the word flux is synonymous with fluidify …

-Fluidification continues to work as pressure and temperature changes in pipeline or conduit

does not evaporate because it incorporates into crude oil mass.

-Continues benefits without adding more Fluidifier additive to crude oil.

-Properly adjusts kinematic viscosity without altering initial composition of crude oil mass by customized formulation.

-Applied in significantly smaller dosages of 0.1% to 0.5% by volume of crude oil treated vs. 10% to 20% by competitive additives which evaporate and require additional treatment.

-The additive components are recovered separately as a saleable product at refinery in each part of distillated fraction to which it corresponds by its evaporation point.

-Dramatically lower operating costs.

-Are environmentally safe non-residual contaminants.

-Can be specially formulated to any dosage strength to meet all crude oil mass fluidification and drag reduction demands.

-Are part of a “building blocks” custom formulated system of additives engineered to perform specific functions, such as fluidification, drag reduction, demulsification, recuperation, wax/paraffin separation, asphaltene inhibition, breaking of the crude oil-water emulsion, cleaning, recovery of crude oil, elimination of incrustations and bacteria, foam prevention, sulfhidric acid reduction, crude oil remediation and performance improvement for the end user.

-Fluidification solves one of the 15 common profit robbing “pain points” in production and flow stream delivery of crude oil.

-Fluidification resulting in more crude oil profit at lower costs, because “Every Drop Counts”.

-Which is why crude oil producers and flow stream handlers should consider using the OilFlux™ additives so that they do not “Choke Your Profits”.

-Fully tested by the renowned testing lab at Intertek.

-Superior to commonly used existing additives such as hexane solvents like naphtha, polymers or organic chemicals which have been around for many decades while exploration, production and flow stream technology have dramatically improved.

-OilFlux™ additives new chemistry now lead crude oil production and flow stream chemical additives into the 21st Century.